Senseeker Sponsors UCSB Engineering Capstone Cryogenic Iris Project

Alex Russell (Lead Mechanical Design Engineer) & Trevor Brake (Mechanical Design Engineer)

After sponsoring two electrical engineering Capstone

projects in recent years with the University of California, Santa Barbara,

(UCSB) College of Engineering, this year Senseeker sponsored its first

mechanical engineering project with the program. For this project, industry

partners and local research labs worked with a group of seniors in the College

of Engineering to work on challenging projects that form the cornerstone of

their educational journey. Our student team consisted of Aamir Rehman, Andrew

Bresk, Eric Lemieux, Eduardo Garcia-Andres, and Daniel Chen.

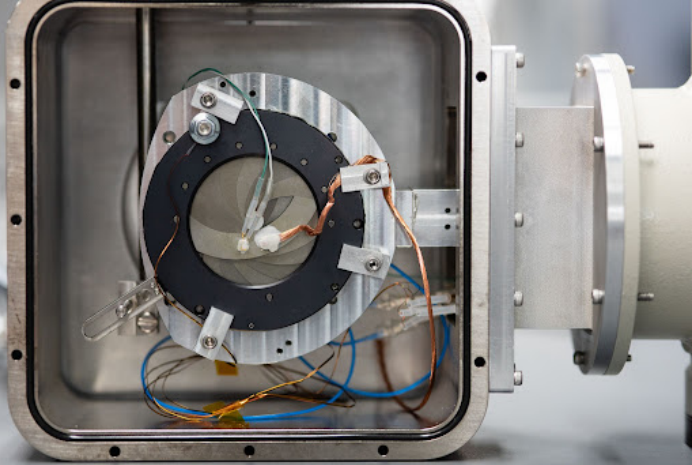

Our student

team was tasked with designing an iris diaphragm that could operate in high

vacuum cryogenic conditions in order to test infrared sensors in Senseeker

Sensor Test Units (STUs). The goal was to design an iris suitable for sensors

that detect mid-wave infrared radiation (MWIR), thus we needed the iris blades

to cool down to around 150 K. Such a device would be very valuable because it

would allow for rapid evaluation of infrared sensors at varying levels of light

flux. Currently in the industry, fixed diameter apertures are used: testing with

a different aperture diameter requires warming up the STU, installing the

aperture, vacuum pumping, then cooling back down. Depending on the size of the

STU, this could amount to a full day of down-time. The challenges in designing

such a device stem from the fact that the iris must be built with materials that

are low-outgassing, thermally conductive, don’t produce foreign object debris

(FOD) and are able to withstand significant thermal shrinkage over a large

temperature delta.

The team started out by designing a liquid nitrogen

test Dewar to evaluate these irises. This Dewar succeeded in pumping down to

4.1e-7 Torr, holding that pressure, and actuating the iris with a linear

mechanical feedthrough. By pouring liquid nitrogen into the Dewar’s

reservoir, the parts inside were capable of cooling down to 80 – 100 K. The

team then started testing a few commercially available vacuum-compatible irises,

of which the best performer only cooled to 223 K - while the rest of the Dewar

was at 95 K - thus confirming the team’s concern that the stainless-steel

blades of the iris and their connection to the housing were too thermally

insulated from each other. With this baseline in mind, the team applied a

special vacuum-compatible grease to the iris blades, which greatly increased

conduction - resulting in an operating temperature of 102 K for the blades as

well as the rest of the Dewar. Exposed to such low temperatures, however, the

grease froze. To address this, the team installed heaters in the Dewar to thaw

the grease so the iris could actuate before cooling down again. Once refined,

this process ended up taking 2.5 hours, which is a vast improvement over the

full day it could take to manually change an aperture. Next, the team

experimented with connecting each iris blade to its housing via copper wire to

increase thermal conduction, which resulted in the blades reaching 133 K while

the rest of the Dewar was at 90 K. This solution met our requirement of < 150 K

operation while allowing the iris to actuate without the warming period

required by the grease.

Senseeker is very happy with the results of this project as we now have a test Dewar capable of testing irises of varying size in the future. The testing done by the students also gave us valuable insight into how to modify typical iris diaphragm mechanisms to adapt them to the demands of cryogenic operation. Senseeker will continue to develop this device and plans to integrate it into its STU product line. We look forward to future projects with the UCSB Capstone Program and appreciate the support of the UCSB faculty.

About Senseeker

Senseeker is a US owned transducer IC and cryogenic test solutions company that specializes in the design of state-of-the-art digital imaging sensors, cryogenic test equipment, electronics and software. Senseeker's products and IP enable FPA developers to produce world class infrared image sensing solutions. Read more at https://www.senseeker.com.