New XL Sensor Test Unit Option Caters for Larger FPAs and More Feedthroughs

Alex Russell (Mechanical Design Engineer) & Ross Bannatyne (Director of Business Development)

February 17, 2022 | Santa Barbara, CA

Senseeker has developed an XL option for the popular Closed-cycle and LN2 pour-fill STUs. The new XL option provides a significantly larger vacuum enclosure in which to accommodate the FPA and all of its electrical connections. The STU’s electrical connections are required to be routed from the FPA to the receiving electronics through the sidewall of the vacuum enclosure. A hermetic connector known as a feedthrough is used for this purpose. With a large FPA there can be hundreds of connections that need to be routed and the amount of space that can be consumed to implement robust low-noise wiring is not likely to be trivial.

The XL STU vacuum enclosure can comfortably accommodate an FPA package/module with dimensions of up to seven inches on a side. We expect this solution to be favored not only for very large sized FPAs but also for FPAs that have many electrical connections or FPAs made up of multiple sensor chip assemblies. When the pin count of an FPA exceeds 150 connections, it starts to get complicated to route all of those internal wires to the feedthrough connectors. This is particularly true when one is following best practices for routing LVDS signal pairs (good practice is to isolate the LVDS pairs with a GND between each). The extra space afforded in the larger DUT vacuum enclosure solves that problem. The more expansive enclosure sidewalls are also conducive to a wider variety of options for the feedthrough connectors.

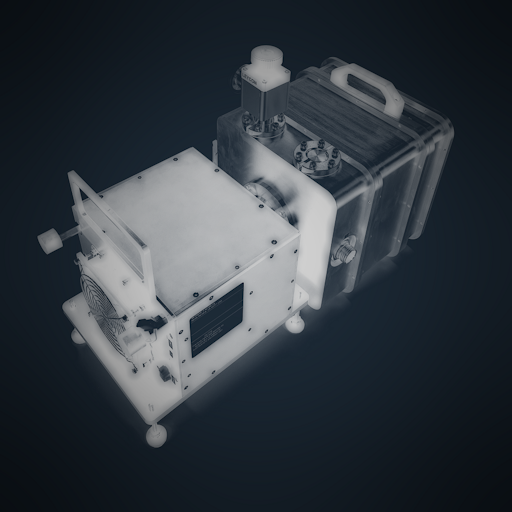

The picture above shows the new XL option of the Closed-cycle STU. The vacuum enclosure portion is nickel plated to improve vacuum quality and the cryocooler is contained in the black anodized housing. Similarly, the new, more generously proportioned vacuum enclosure can be attached to an LN2 pour-fill Dewar. For the Closed-cycle STU with the XL option, the cryocooler has been upgraded from the CryoTel® CT cryocooler to the CryoTel® GT cryocooler so as to accommodate the larger thermal mass inside the XL STU. This upgrade increases the cooling at 77 K from 11 W to 16 W, thus providing a comparable thermal time constant and ensures that testing can be conducted as expediently as possible.

We’re aiming to simplify and accelerate FPA testing by providing equipment that is easy to use and maintain, quick to bring-up and is robust enough for many years of use in an engineering lab. After the FPA has been thoroughly tested in the STU it can be relocated into a SWaP optimized Integrated Dewar Cooler Assembly (IDCA) for production purposes.

Talk to us about your specific large FPA cryogenic testing needs.

About Senseeker

Senseeker is a US owned transducer IC and cryogenic test solutions company that specializes in the design of state-of-the-art digital imaging sensors, cryogenic test equipment, electronics and software. Senseeker's products and IP enable FPA developers to produce world class infrared image sensing solutions. Read more at https://www.senseeker.com.

Media contact: info@senseeker.com | 1 (805) 617-0337

Press Release # PR-20220217